There have been some electrical problems for some time now, with the Brawa V100 going through this long switch, whose installation was covered

here. When the locomotive would be going slow, in the position marked by the two red pins, it will lose power. Using an electrical measuring tool soon showed that the frog rails weren't receiving any power (the frog rails are the fixed rails that go "out" of the frog).

Fixing it would have been possible using Tillig's 85506 contact clips, but as with the rail joiners, electrical conductivity isn't that reliable. Only thing that would make sure the original issue goes away was soldering a wire to the frog rails.

Un-mounting the switch however wasn't that easy, since the rail joiners only slided completely at the upper end (by pushing the ties a bit; even if secured to the foam, the latter allowed just enough movement). For the other 2 ends -since 2 isolating Tillig joiners are used for the 2 frog rails, the rails had to be physically lifted to allow removal. Alcohol was used, using a pipette so that the drops could reach between the ties. After a few applications and a couple more minutes, the ties came loose and the switch lifted from its support.

In the second photo the cause of the problems can be seen: the metal piece joining both the frog rails (now soldered to the red wire) and rails inside the frog itself (now soldered to the brown wire; also it's clearly visible where these end, before the point blades themselves start) was secured in a faulty manner when this switch was build - resulting in poor connectivity. Cleaning of the metal spots and the soldering itself was done as mentioned in the article at the beginning. Even though the original problem consisted of the frog rails lacking electrical connectivity, I went ahead and soldered a wire to the frog itself, so this all this removal operation won't be needed in the future. Even if first decided to remove the violet wire soldered to the metal piece, I re-soldered it thinking that there's no harm in an extra point of contact.

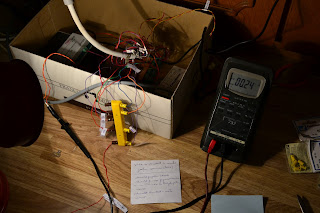

All 3 wires were connected to the Tillig's 86112 white wire. The third photo shows how the switch looks like installed in its place. Some ballast must be glued so that the remaining holes can be hidden, and also some weathering powders to make the soldered wires invisible

The way the wires are connected together under the board is presented below for future reference:

I - blue, green, green, violet (the latter is the wire secured to blade associated with the inner route)

II - brown, yellow, yellow, blue(the latter is the wire secured to the blade associated with the outer route)

The rod connecting to sliding tie to the Tillig motor was cut to size also. One important warning is to secure the screw holding the rod, otherwise symptoms like the ones mentioned

here can appear.

A very good guide for assembling the Tillig switch kits can be found

here.